Kemzymes bring sustainability, performance and cost competitiveness to denim garment washing

Kemin Industries, a global ingredient manufacturer that strives to sustainably transform the quality of life every day for 80 percent of the world with its products and services, announced today that Garmon Chemicals (Garmon), the Kemin Textile Auxiliaries business unit, has launched Kemzymes, a new range of enzymes developed specifically for garment washing, to become the first textile chemical company to produce its own enzymes.

When Kemin acquired Garmon in 2018, the two companies came together with the goal of revolutionizing the garment finishing industry. By bringing Kemin’s scientific expertise and innovation to the brand of the chemical solution for the denim and fashion industry, Garmon was able to move forward with research that was once out of reach for its customers.

After investing two years of research into its newest product range, Garmon was able to apply the superior science of Kemin to its knowledge and experience in garment finishing to become the first textile chemical company to self-produce a range of enzymes not found in any other industry products. Kemzymes offers an unparalleled combination of sustainability, performance and cost competitiveness.

The first Kemzymes products available are two lines of stone washing enzymes: Kemzymes KS and Kemzymes K.

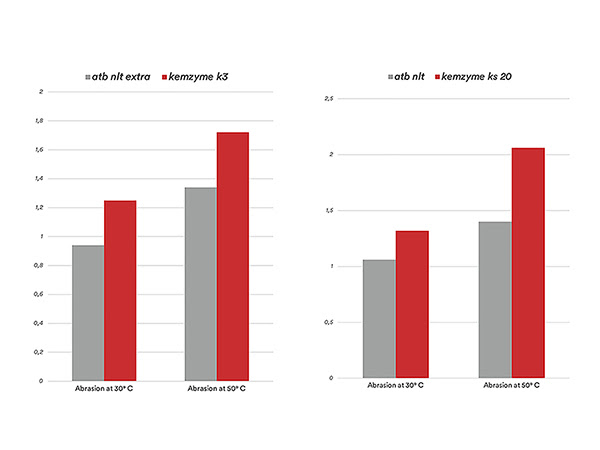

Kemzymes KS are the uncompromised, concentrated version of Garmon’s new neutral cellulase enzymes for denim stone washing. Designed to work at room temperature and included in the ZDHC Gateway, Kemzymes KS open the possibility to truly eliminate the use of pumice stones.

Kemzymes K, also included in the ZDHC Gateway, are strong powder enzymes for denim stone washing. Delivering a perfect combination of abrasion power, sustainable characteristics and superior value for its price point, Kemzymes K are designed to become the best seller of denim stone washing enzymes for all types of industrial laundries.

“As the first textile chemical company to produce our own enzymes – not just blend them, as many do – we set our own standards very high,” said Kimberly Nelson, President, Kemin Textile Auxiliaries. “The textile chemicals market is saturated with options, but they do not create the results Kemzymes achieves. To continue distinguishing Garmon as a brand with research-backed products and proven solutions, the performance was the key target when we developed Kemzymes.”

Relentlessly tested by dedicated teams using the most modern equipment available, Kemzymes looked to Kemin’s expertise in enzymes and Garmon’s historical success with chemical solutions to improve on every aspect possible. For Garmon, sustainable performance and beautiful vintage looks are the minimum – the brand has raised the bar on nearly every other aspect of garment finishing. As its latest solution, Kemzymes are so precise they outperform every other popular enzyme used in the denim-washing industry – even Garmon’s own previous products.

Kemzymes KS and K are available now for testing in most international markets. For more information, visit www.garmonchemicals.com or contact local sales agent.