Bangladesh’s readymade garment (RMG) industry will be seriously impacted by the new US tariffs, with industry leaders calling it a “bolt from the blue” that could disrupt trade and reduce the country’s competitiveness in the American market.

Talking to The Business Standard today (3 April), Sparrow Group Managing Director Shovon Islam noted that the 37% increase is an additional tariff, meaning the total duty on RMG cotton-blend products will now stand at 54% (37% + 17%).

“Bangladesh is among the countries hit with one of the highest tariffs,” he said, pointing out that after this increase, Bangladesh’s tariff rate will be almost equivalent to that of China’s cotton products.

While India and other competitors have also faced tariff hikes, Bangladesh’s tariff rate will now be higher than India’s, making it less attractive for buyers, he said.

Earlier today, US President Donald Trump announced that the US is imposing reciprocal tariffs to match duties placed on US goods by other countries.

During an event at the White House Rose Garden, Trump displayed a poster listing reciprocal tariffs, which included a 37% duty on Bangladeshi products as a response to 74% duties imposed on goods imported from the US.

Trump also announced a 10% baseline tariff on all imports and higher duties on some of the country’s biggest trading partners.

In response to Trump’s announcement, the interim government has said it is currently reviewing the tariffs on US imports.

“The National Board of Revenue is identifying options to rationalise tariffs expeditiously, which is necessary to address the matter,” Chief Adviser’s Press Secretary Shafiqul Alam said in a statement posted on Facebook this morning.

New sourcing alternatives

Shovon, a former director of BGMEA, stressed that buyers are already shifting to Jordan, Egypt, and Kenya as alternative sourcing destinations.

“We are experienced in producing MMF [man-made fibre] products, but after the tariff hike proposal, we received requests from buyers to produce cotton-based products in Jordan, as their tariff rates remain lower than Bangladesh’s,” he said.

The US has imposed only a 20% duty on cotton product imports from Jordan, making it a more attractive sourcing hub than Bangladesh.

Shovon warned that the immediate impact of the tariff hike would include disruptions in goods shipments and potential delays in payments. In some cases, payments may even be withheld, similar to what happened during the Covid-19 pandemic.

‘If govt eliminates duties, engages in diplomatic efforts to lift US tariff, Bangladesh could establish duty-free trade ties’

If the government eliminates its duties and engages in diplomatic efforts to lift the US tariff, Bangladesh could establish a duty-free trade relationship, said Md M Mohiuddin Chowdhury, a member of the BGMEA administrative committee and Director of Clifton Fashion Ltd.

“This would be a game-changer,” he said.

The BGMEA has already raised the issue with the chief adviser, and a plan is being developed, and that the government is expected to take steps soon to secure duty-free access to the US market, he claimed.

He also stated that the Bangladesh garment industry will face immediate setbacks due to a new 37% tariff imposed by US President Donald Trump.

This tariff, he said, will lead to the loss of several work orders currently in the pipeline. However, he remains optimistic, adding, “There’s a significant opportunity for duty-free trade with the US, which could usher in a new era for us.”

Explaining the tariff, Chowdhury described it as a “reciprocal measure”—a response to Bangladesh’s 74% duty on imported American goods. “The US has now imposed a 37% tariff in return,” he said.

He pointed out that Bangladesh imports only a small volume of machinery for development and food grains to support its population.

What should Bangladesh do?

To mitigate the impact of the tariff hike, industry leaders have suggested that Bangladesh should take a two-pronged approach — first, by offering zero-duty access for US agricultural products, including cotton, and second, by increasing imports from the US.

Allowing duty-free access to US agro products would encourage direct purchases from the US instead of Brazil and other countries, potentially easing trade tensions. Additionally, increasing imports of military equipment and ammunition could help balance the trade deficit.

Shovon noted that Trump has been advocating for such tariffs since 1988 as part of his efforts to reduce trade deficits with business partners.

Meanwhile, Sri Lanka has already proposed zero duty for all US imports, and India is also considering further tariff reductions.

In summary, he said the new tariffs will lead to a major shift in sourcing. “Favored destinations will Egypt, Jordan, Kenya, and Turkey.”

“Orders will stop moving from China to Bangladesh completely. Actually, some orders will move back to China as there is no duty difference between Bangladesh and China. Sweater and Jacket manufacturing will be greatly impacted,” he said.

“It was still too early to call, but the impact will be devastating for Bangladesh, Vietnam, Cambodia and Sri Lanka,” he added.

Trump’s tariff calculations questioned

Syed M Tanvir, managing director of Pacific Jeans Ltd, told TBS that the tariff formula or numbers used by the Trump administration do not necessarily reflect the actual rates Bangladesh charges.

“Trump’s team derived these figures by factoring in the trade deficit and export values, not just existing tariff rates,” he said.

While Trump called it “reciprocal”, Tanvir pointed out that it is not based on the actual tariff Bangladesh imposes, but rather a formula developed by his economists.

In 2024, total US goods trade with Bangladesh was $10.6 billion, with US exports to Bangladesh at $2.2 billion, while imports from Bangladesh stood at $8.4 billion. This resulted in a US trade deficit of $6.2 billion, a 2% increase from 2023.

According to Tanvir and Shovon Islam, the formula used for tariffs:

Trade Deficit ÷ Imports to the US from that country (in billion dollars)

- Bangladesh: 6.2 ÷ 8.4 = -74% → Tax halved to 37%

- India: 45.7 ÷ 87.4 = -52.3% → Tax set at 26%

- Pakistan: 3 ÷ 5.1 = -58.8% → Tax set at 29%

- Indonesia: 17.9 ÷ 28 = -64% → Tax set at 32%

- Vietnam: 123.5 ÷ 136.6 = -90% → Tax set at 46%

To mitigate the impact, Bangladesh must increase its imports from the US, including arms, machinery, fighter jets, and ships, to help balance trade and reduce the deficit, said Tanvir.

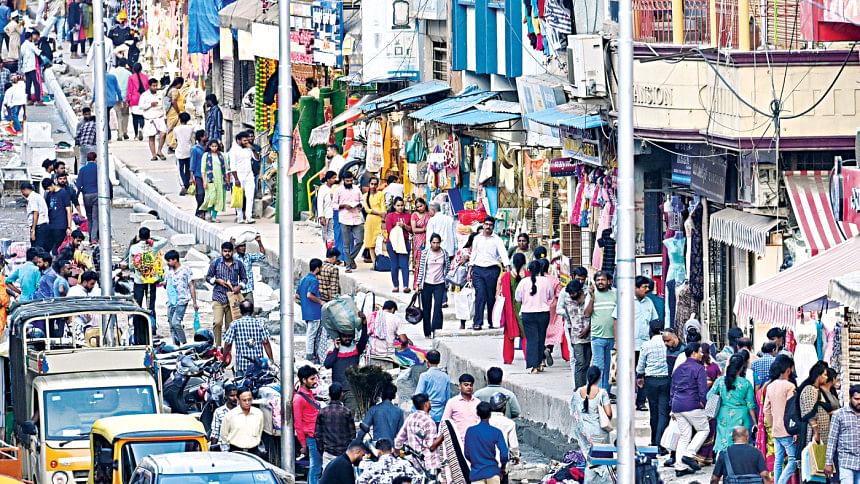

The bar chart shows the tariff rates across Asia countries. Photo: Reuters

“Negotiation and diplomacy will be crucial, but Trump is unlikely to budge unless there’s something in it for him,” Tanvir said. “He’s a dealmaker, not a traditional politician. Bangladesh has to give him something to get something in return.”

Concerns over LDC graduation

Shams Mahmud, managing director of Shasha Denim Ltd, told TBS the new tariffs raise critical issues for Bangladesh, particularly as it prepares to graduate from its Least Developed Country (LDC) status.

“Bangladesh now finds itself facing higher tariffs for exports to the US than our competitors,” he said.

He also raised concerns over foreign companies relocating from China to Bangladesh to take advantage of US market access, saying this shift is now in question.

“Our tax collection system, which heavily relies on import duties, now needs to be reviewed in light of these tariffs,” Shams added.

“Most importantly, as Bangladesh moves towards LDC graduation, this new scenario means the transition will not be smooth. It raises the question of whether graduation should be re-evaluated,” he added.

With Bangladesh’s RMG sector being severely impacted, Shams warned that the country’s macroeconomic stability will now come under stress.

Major threat to Bangladesh’s RMG sector

Meanwhile, former BGMEA vice president Rakibul Alam Chowdhury warned that the newly imposed 37% tariff by the US is expected to severely impact the RMG sector.

“It is a major threat for us. Our competitors, India and China, will benefit from the new tariff structure as their rates are comparatively lower than Bangladesh’s,” he told TBS.

He explained that buyers bear the cost of duties, and if US buyers find that the added tariff increases the product price beyond their market threshold, they will seek alternative sourcing to minimise costs.

Meanwhile, rising costs of manufacturing — driven by wage hikes and soaring inflation — are making it increasingly difficult for Bangladeshi manufacturers to stay competitive, Rakibul said.

Trump stokes trade war as world reels from tariff shock

“We are in discussions with buyers to maintain orders already in the pipeline. They, too, are assessing the situation and looking for a viable solution,” he added.

Addressing the 74% tariff imposed by Bangladesh on US products, Rakibul noted that the country imports very little from the US.

“Imposing such a high tariff is unrealistic, which prompted the US government to introduce this new tariff,” he remarked.

He urged the government to reassess its tariff policy and engage in diplomatic efforts to convince the US to withdraw the new tariff.

“Otherwise, our RMG sector will be in serious danger,” he warned.