বিদেশি চক্রান্তে গার্মেন্টসে অস্থিরতা!

রপ্তানিমুখী তৈরি পোশাক শিল্প এখন সংকটে। কথায় কথায় কারখানায় বিক্ষোভ, ধর্মঘট, আন্দোলন আর দাবিদাওয়ার কবলে পড়ে ক্রয়াদেশ ও উৎপাদন ঝুঁকিতে। নানা ছুতায় কর্মীরা অপ্রচলিত ইস্যু সামনে এনে কারখানা বন্ধ করে দেওয়ার ফলে খারাপ বার্তা যাচ্ছে বহির্বিশ্বে। বৈদেশিক মুদ্রা আয়ের অন্যতম প্রধান এই খাত নিয়ে এখন প্রশ্ন উঠছে ষড়যন্ত্রের।

উদ্যোক্তাদের মধ্যে চরম উদ্বেগ ছড়িয়ে পড়ছে। সরকারের শত প্রচেষ্টার মধ্যেও শিল্পে স্থিতিশীলতা না ফেরায় তাঁরাও এর পেছনে আন্তর্জাতিক চক্রের শিল্প ধ্বংসের ইন্ধন রয়েছে বলে আশঙ্কা করছেন। তাঁরা বলেন, আর্থিকভাবে দেশের সবচেয়ে গুরুত্বপূর্ণ এই খাতকে ধ্বংস করার জন্য পরিকল্পিত ষড়যন্ত্র করা হচ্ছে। অন্তর্বর্তী সরকারকে বেকায়দায় ফেলতে বিদেশি অদৃশ্য শক্তি টাকা ছিটিয়ে দেশি এজেন্টদের দিয়ে শিল্পাঞ্চলগুলোকে অস্থিতিশীল করার জন্য পর্দার আড়ালে কলকাঠি নাড়ছে বলেও তাঁদের ধারণা।

এদিকে গতকালও অস্থিতিশীলতা তৈরির আশঙ্কায় সাভার, আশুলিয়া ও গাজীপুরের অন্তত ৬০টি কারখানা বন্ধ করে দেওয়ার ঘটনা ঘটে। উদ্ভূত পরিস্থিতিতে জরুরি বৈঠক করেন পোশাকশিল্প মালিকরা। অন্যদিকে শ্রমিকরাও অবিলম্বে বাস্তবায়নের জন্য শ্রম মন্ত্রণালয়ে তাঁদের ১৮ দফা দাবি জমা দিয়েছেন।

জানা যায়, অন্তর্বর্তী সরকার ক্ষমতা নেওয়ার পর থেকেই পুরো পোশাক খাত একটি খারাপ সময় পার করছে। কয়েক মাস আগে বেতনসহ সুযোগ-সুবিধা বাড়ানোর পরও থেমে থেমে নানা দাবিদাওয়া নিয়ে মাঠে নামছে কর্মীদের একাংশ। শ্রমিকদের আগের সরকারের দলীয় একটি চক্রসহ আরো নতুন নতুন গোষ্ঠী প্রশ্রয় দিচ্ছে বলে অভিযোগ রয়েছে। এর ফলে সরকারের নানা প্রচেষ্টার পরও পরিস্থিতি স্বাভাবিক করা যাচ্ছে না। এমনকি সেনাবাহিনীকে নির্বাহী ক্ষমতা দেওয়ার পরও থামছে না অস্থিরতা। এ জন্য নেপথ্যে দেশি-বিদেশি ষড়যন্ত্রের আশঙ্কা করা হচ্ছে।

পোশাক খাতে অস্থিরতার ফলে ক্রয়াদেশ কমে যাচ্ছে বলে জানিয়েছেন উদ্যোক্তারা। কেউ কেউ বলছেন, তাঁদের ২৫ থেকে ৩০ শতাংশ পর্যন্ত ক্রয়াদেশ কমে গেছে। বৈশ্বিক ক্রেতারা ভারতসহ অন্য দেশে তাদের ক্রয়াদেশ স্থানান্তর করছে বলে জানা গেছে। পরিস্থিতি যখন ক্রমেই খারাপ হচ্ছে, তখন ভারতে পোশাকের ক্রয়াদেশ ১২ শতাংশ বেড়েছে বলে খবর প্রকাশিত হয়েছে।

এদিকে পোশাক খাতে অস্থিরতার পেছনে একটি চক্রের ইন্ধন দেওয়ার কথা শোনা যাচ্ছে। কালের কণ্ঠের এই প্রতিবেদকের কাছে একটি ভিডিও এসেছে, যেখানে একজন নারী শ্রমিক নেত্রীকে আগের সরকারকে ফেলে দেওয়ার ধারাবাহিকতায় প্রয়োজনে বর্তমান সরকারকেও ফেলে দেওয়ার হুমকি দিতে শোনা যায়।

বিভিন্ন সূত্র থেকে আরো জানা যায়, আগের সরকারের দলীয় সুবিধাভোগীদের একটি অংশ এর সঙ্গে জড়িত। পালিয়ে যাওয়া অনেক নেতা আবারও পোশাক শিল্পাঞ্চলে ফিরতে শুরু করেছেন।

এ প্রসঙ্গে বাংলাদেশ গার্মেন্টস শ্রমিক ঐক্য পরিষদের চেয়ারম্যান মো. তৌহিদুর রহমান কালের কণ্ঠকে বলেন, ‘পোশাকশিল্পের চলমান অস্থিরতার ফলে লাভবান হচ্ছে প্রতিযোগী দেশ ভারত। সম্প্রতি ভারতে রপ্তানি বেড়েছে, আর দেশের কর্মসংস্থান কমছে। আওয়ামী লীগ সরকারের সুবিধাভোগী বড় বড় পোশাক ব্যবসায়ীর নজরদারিতে আনলেই এর প্রকৃত রহস্য বের হয়ে আসবে। পরিস্থিতির অবনতিতে কার্যাদেশ এবং বিদেশি ক্রেতারা মুখ ফিরিয়ে নিলে দেশের অর্থনীতির অপূরণীয় ক্ষতি হবে।’

নাম প্রকাশ না করার শর্তে পোশাক খাতের একজন উদ্যোক্তা বলেন, দেশের পোশাকশিল্পে অস্থিরতায় ভারতে রপ্তানি আয় বাড়ছে। গত বছরের তুলনায় চলতি বছরের আগস্টে তাদের রপ্তানি বেড়ে দাঁড়িয়েছে ১২ শতাংশ। শুধু আগস্টেই তাদের আয় হয়েছে ১২৬ কোটি ডলার। এপ্রিল থেকে আগস্ট পর্যন্ত রপ্তানি থেকে ভারতের আয় হয়েছে ৬৩৯ কোটি ডলার। দেশটির বাণিজ্য মন্ত্রণালয়ের তথ্য উল্লেখ করে তিনি বলেন, বাণিজ্যযুদ্ধ, ভূ-রাজনৈতিক অস্থিরতার পাশাপাশি লজিস্টিক খরচ ও মূল্যস্ফীতির মতো সমস্যাগুলোকে পাশ কাটিয়ে রপ্তানি বাড়াতে সক্ষম হয়েছে ভারত।

বাংলাদেশের পোশাক খাত নিয়ে দেশি ও বিদেশি গভীর ষড়যন্ত্র কাজ করছে। এর মধ্যে রাজনীতিও ঢুকে পড়েছে উল্লেখ করে নিট পোশাক খাতের সংগঠন বিকেএমইএর নির্বাহী সভাপতি ফজলে শামিম ইহসান কালের কণ্ঠকে বলেন, ‘এই শ্রমিক আন্দোলন কোনো সাধারণ আন্দোলন নয়। এখানে বিদেশি শক্তি ঢুকে পড়েছে। ফলে শ্রমিক আন্দোলনের নামে দেশের পোশাকশিল্পসহ সরকারকে অস্থিতিশীল করতে বহিরাগতরা এসব করছে। এই আন্দোলনে বিপুল অর্থ ব্যয় করা হচ্ছে। বেকার যুব সংগঠনের নামে কারখানা ভাঙচুর করছে। এটা কোনো শ্রমিকের কাজ নয়।’

দেশের পোশাক খাতে চলমান অস্থিরতার পেছনে বিদেশি ইন্ধন রয়েছে বলে মনে করেন শ্রম ও কর্মসংস্থান সচিব এ এইচ এম সফিকুজ্জামান। গত শনিবার এক অনুষ্ঠানে তিনি বলেন, ‘ভুল তথ্য ছড়িয়ে একটি মহল শিল্প এলাকায় অস্থিরতা সৃষ্টি করেছে। এ খাতে অস্থিরতা দীর্ঘায়িত হলে ক্রয়াদেশ অন্য দেশে চলে যেতে পারে।’

এদিকে শ্রম ও কর্মসংস্থান মন্ত্রণালয়ের সচিবের সঙ্গে গতকাল গার্মেন্টসশিল্প সেক্টরের শ্রমিক নেতাদের বৈঠক হয়। এ সময় শ্রমিক নেতারা ১৮ দফা দাবি জানান। এর মধ্যে মজুরি বোর্ড পুনর্গঠন ও শ্রমিকদের ন্যূনতম মজুরি পুনর্নির্ধারণ অন্যতম। শ্রমসচিব জানিয়েছেন, চলমান শ্রম পরিস্থিতি নিয়ে আজ দুপুরে শ্রম মন্ত্রণালয়ের উপদেষ্টা আসিফ মাহমুদ সজীব ভূঁইয়া অন্তর্বর্তী সরকারের চার উপদেষ্টাকে নিয়ে সংবাদ সম্মেলন করবেন। এতে মালিক ও শ্রমিক পক্ষের প্রতিনিধিরা উপস্থিত থাকবেন।

মন্ত্রণালয় সূত্রে শ্রমিকদের দাবি সম্পর্কে জানা যায়, মজুরি বোর্ড পুনর্গঠনপূর্বক শ্রমিকদের ন্যূনতম মজুরি পুনর্নির্ধারণ করতে করা। ২৭ কারখানায় ন্যূনতম মজুরি দ্রুত বাস্তবায়ন করা, চাকরি পাঁচ বছর পূর্ণ হওয়ার পর চাকরি থেকে অব্যাহতি দিলে একটি বেসিকের সমান অর্থ প্রদান করা, সাংঘর্ষিক শ্রম আইনের ১৭ ধারাসহ অন্যান্য ধারা সংশোধন করা, বকেয়া মজুরি পরিশোধ, বেতনের বিপরীতে বার্ষিক ইনক্রিমেন্ট ন্যূনতম ১০ শতাংশ নির্ধারণ, শ্রমিকদের জন্য রেশনব্যবস্থা, বিজিএমইএ কর্তৃক নিয়ন্ত্রিত বায়োমেট্রিক কালো তালিকা না করা, বায়োমেট্রিক তালিকা সরকারের নিয়ন্ত্রণে রাখা, সব ধরনের হয়রানিমূলক ও রাজনৈতিক মামলা প্রত্যাহার, ঝুট ব্যবসার আধিপত্য বন্ধে আইন করা, কলকারখানায় বৈষম্যবিহীন নিয়োগ প্রদান করা, জুলাই বিপ্লবে শহীদ ও আহত শ্রমিকদের ক্ষতিপূরণ ও চিকিৎসাসেবা নিশ্চিত করা, রানা প্লাজা ও তাজরীন ফ্যাশন দুর্ঘটনায় ক্ষতিগ্রস্তদের কল্যাণের জন্য তদন্ত করা, শ্রম আইন অনুযায়ী সব কারখানায় ডে-কেয়ার সেন্টার স্থাপন, অন্যায্যভাবে শ্রমিক ছাঁটাই বন্ধ করা এবং মহিলা শ্রমিকদের মাতৃত্বকালীন ছুটির মেয়াদ ১২০ দিন নির্ধারণ করা।

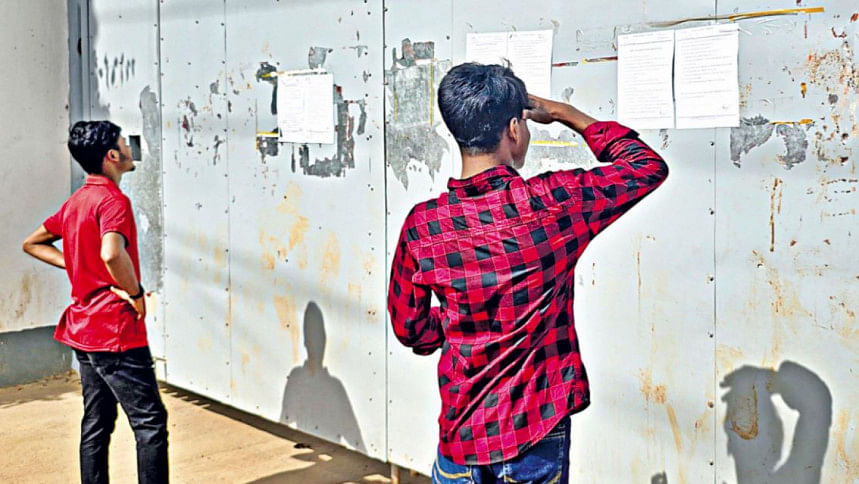

গাজীপুরে চাকরির দাবিতে বিক্ষোভ-ভাঙচুর, সড়ক অবরোধ, ৬০ কারখানায় ছুটি

নিজস্ব প্রতিবেদক, গাজীপুর জানান, গতকাল সোমবারও চাকরিতে পুনর্বহালসহ বিভিন্ন দাবিতে গাজীপুরের বেশ কয়েকটি স্থানে পোশাক কারখানার শ্রমিকরা বিক্ষোভ ও সড়ক অবরোধ করে। অবরোধের কারণে সকাল ৯টা থেকে ১১টা পর্যন্ত ঢাকা-ময়মনসিংহ মহাসড়কে যানবাহন চলাচল বন্ধ থাকে। এ সময় উত্তেজিত শ্রমিকরা নগরীর চান্দনা চৌরাস্তা, চৌধুরীবাড়ি, ভোগড়া বাইপাস, ছয়দানা হারিকেন, কাশিমপুর ও টঙ্গীতে বেশ কয়েকটি কারখানায় ইটপাটকেল নিক্ষেপ করে ভাঙচুর করেন। বিক্ষোভ করেন সাইনবোর্ড, জিরানি বাজার, কোনাবাড়ী, বাসন, বাঘের বাজারসহ বিভিন্ন এলাকায়। শ্রমিক অসন্তোষের কারণে গতকাল গাজীপুরে ৬০টি কারখানায় ছুটি ঘোষণা করা হয় বলে জানান গাজীপুর শিল্প পুলিশের অতিরিক্ত পুলিশ সুপার ইমরান আহমেদ।

গার্মেন্টস শ্রমিক নেতা আরমান হোসাইন বলেন, ‘বাংলাদেশ বেকার সংগঠনের কর্মীদের সঙ্গে গত মঙ্গলবার আমরা আলোচনা করেছি। গতকাল থেকে তাঁদের কোনো কর্মসূচি থাকার কথা ছিল না। তাঁরা প্রতিশ্রুতি দিয়েছিলেন, সরকারি উচ্চপদস্থ কর্মকর্তাদের কাছে বেকারত্বের বিষয়গুলো তুলে ধরবেন। এ বিষয়ে শিল্প পুলিশের পুলিশ সুপার তাঁদের সহযোগিতা করার আশ্বাস দিয়েছিলেন। কিন্তু তার পরও সকালে কয়েক শ লোক ভোগড়া বাইপাসে একত্র হয়ে আন্দোলনে নামেন।’

গাজীপুর শিল্প পুলিশের অতিরিক্ত পুলিশ সুপার ইমরান আহমেদ বলেন, ‘বিক্ষোভ চলাকালে টঙ্গীতে ইস্ট ওয়েস্ট ইন্ডাস্ট্রিয়াল পার্ক, কাশিমপুরে গ্রামীণ টেক্স, ডরিন গার্মেন্টস ও নরভান গার্মেন্টস কারখানায় বিক্ষুব্ধ শ্রমিকরা ইটপাটকেল নিক্ষেপ করে ভাঙচুর চালান। কারখানা কর্তৃপক্ষ ও শ্রমিকদের সঙ্গে আলোচনা করে দাবি মেনে নেওয়ার আশ্বাসের পরিপ্রেক্ষিতে আন্দোলনকারীরা মহাসড়ক ছেড়ে চলে যান।’

শ্রীপুরে সিরামিক কারখানায় শ্রমিকদের বিক্ষোভ

আঞ্চলিক প্রতিনিধি, গাজীপুর জানান, গাজীপুরের শ্রীপুরে ১১ দফা দাবিতে একটি সিরামিক কারখানার শ্রমিকরা গতকাল সকাল সাড়ে ৭টা থেকে দফায় দফায় ঢাকা-ময়মনসিংহ মহাসড়ক অবরোধ করে বিক্ষোভ করেছেন। সকাল ১১টার দিকে সেনাবাহিনীর একটি টহল দল ও শিল্প পুলিশ সেখানে পৌঁছে কারখানার মালিকপক্ষের সঙ্গে আলোচনার মাধ্যমে সুরাহার কথা বললে অবরোধ প্রত্যাহার করেন শ্রমিকরা।

উপজেলার ধনুয়া এলাকায় আরএকে সিরামিক বিডি লিমিটেড কারখানার শ্রমিকরা এই আন্দোলন করেন।

আন্দোলনরত শ্রমিকরা জানান, কারখানার কর্মকর্তাদের মধ্যে কয়েকজন ভারতের নাগরিক রয়েছেন। তাঁদের অপসারণ করতে হবে। এ ছাড়া বাজারের বর্তমান প্রেক্ষাপট অনুযায়ী মজুরি ও বার্ষিক মজুরি বৃদ্ধিসহ (ইনক্রিমেন্ট) তাঁদের ১১ দফা দাবি রয়েছে।

পোশাক খাতে অস্থিরতা চলছেই, আবার বসল বিজিএমইএ

গতকাল উত্তরায় সংগঠনের নিজস্ব কার্যালয়ে উদ্যোক্তাদের ‘জরুরি মতবিনিময়সভা’য় ডাকা হয়। বৈঠকে সংগঠনটির সাবেক সভাপতি, সদস্য কারখানাগুলোর মালিক, সেনাবাহিনীর প্রতিনিধি, শিল্প পুলিশ, গোয়েন্দা সংস্থা এনএসআইসহ বিভিন্ন অংশীজন। এ সময় তাঁরা পরিস্থিতি নিয়ে চরম হতাশা প্রকাশ করেন এবং অবিলম্বে স্থিতিশীলতা ফিরিয়ে আনার দাবি করেন।