They want to pass the ball on to the government and the buyers

The government has done its job by hiking the gas prices by 150% for large industries and 178% for small, cottage and other industries. Now it is the job of the exporters and manufacturers how they will handle these additional costs at a time when they are facing a decline in orders from buyers in the West because of a looming recession there.

Accordingly, they have started calculating how they can pass the additional costs on to the buyers and the government.

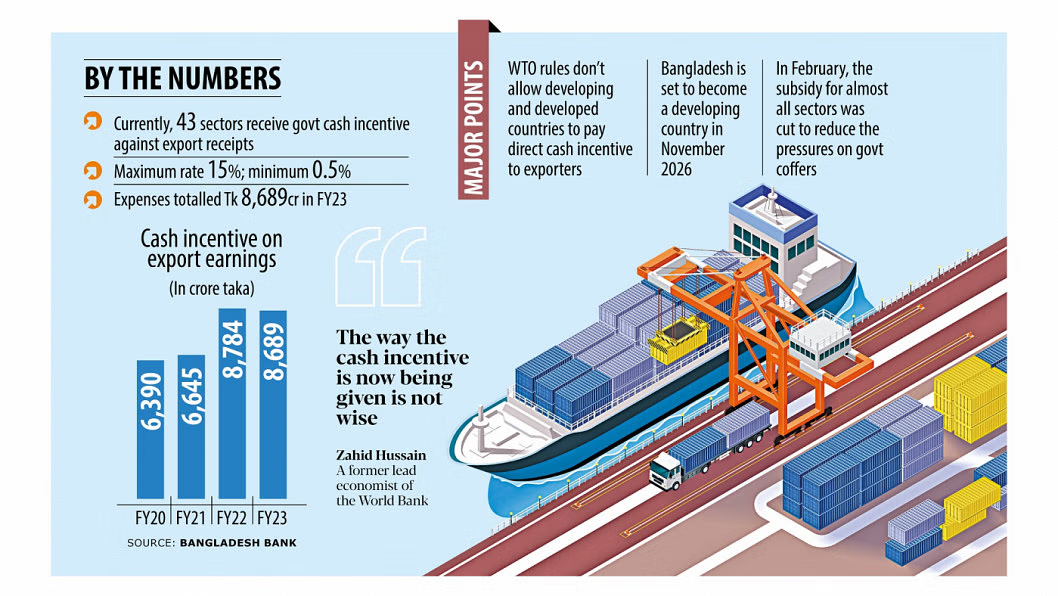

Considering the overall energy situation, the Bangladesh Textile Mills Association (BTMA) has already demanded an increase in alternative cash incentive facilities to 7% from 4% to remain competitive in the global markets and meet the government-set export target, BTMA CEO (current charge) Monsoor Ahmed told The Business Standard.

He said the association raised their demand during a meeting with the Ministry of Commerce on Wednesday.

The BTMA also requested introducing a 15% cash incentive against the man-made fibre-based export. “This 15% incentive should be for the next five years as a number of textile mills are investing in this sector to diversify the export basket within the apparel sector,” he told The Business Standard.

Otherwise, he said textile millers will have to eat up their capital to run their business.

Kutubuddin Ahmed, founder of the country’s one of the leading apparel manufacturing units Envoy Textile Mills, called for some sort of relief measures by the government, such as withdrawal of 1% AIT (advance Income tax) on industries or increasing cash incentive for the readymade garment exporters.

Sharif Zahir, managing director of Ananta Group, said the gas hike will escalate apparel sector utility up to 8% from current 3%-4%. “It will hit our profit margin as many factories are now running with 15%-20% of the production capacity sitting idle due to the global economic slowdown.”

Besides, there is no scope for price negotiation with the buyers now, he said, adding, “Gas will now cost us as much as diesel”.

Adzi Trims Ltd’s Managing Director Al Shahriar Ahmed said his group is paying about Tk30 crore to Tk32 crore as utility bills, but it will almost double now on.

“We have no idea how we will adjust the additional costs,” he added.

Bangladesh Knitwear Manufacturers and Exporters Association Executive President Mohammed Hatem said if the government does not increase alternative cash incentive facilities, a large number of factories will be out of business since most of them are running at breakeven cost.

Md Shofiqur Rahman, executive director of Zaber and Zubair Fabrics Ltd, said they will seek a hike from the Western buyers.

“We will ask for the additional costs though those products are yet to be delivered,” he added.

He also mentioned that the apparel business has been reduced for the next fall–winter season compared to 2021 due to the war-led global economic slowdown.

He further explained that earlier buyers were committed to a large volume and places those POs step by step but now they mentioned a volume and places one fifth of that but they are not committed to procure the full amount, if they get positive response from buyers, they may place rest of orders as speed orders (orders for quick delivery).

Exporters should maintain an inventory of raw materials and if those buyers are not placed, those investments go to risky situations, said Rahman.

Due to the new buying pattern (speed orders) buyers may not have scope to shift their buying destinations immediately, added executive director seals marketing at Zaber and Zubair fabrics ltd.

He said Bangladesh will lose competitiveness for fast fashion due to this additional cost.

Insiders said some of the exporters have already informed their buyers the overall situation and sought their support to adjust this additional cost, saying that they are doing business at breakeven level or below that level.

However, buyers are not ready yet to pay this additional cost at least within the next 6 months as they are also facing pressure from the Russia-Ukraine war.

In response to fabric exporters’ arguments, asking for anonymity , a multinational buying house head of business development said, this additional cost adjustment will not be possible within the next six months, as our buyers also have no scope to increase the selling prices, their currency also faces inflationary pressure.

“If the retailers want to adjust this additional cost they have to increase their selling prices by at least 1-2 dollars, which is not possible at this moment, that’s why we are trying to maintain the same price”.

In the last month, we informed our buyers that the Bangladesh apparel industry might face utility price hikes from January that may increase the yarn and fabric prices but this type of massive hike was out of our expectation, he added.

However, G-Star RAW that sourced $70 million worth of garments in 2021 is an exception.

Shafiur Rahman, Country manager at G-Star RAW said “Today (Thursday) we have discussed with headquarters over the situation, our mindset is sourcing apparel paying this additional cost as every sourcing country is facing the same.”

“We are committed to maintain ethical buying practices in our supply chain”, he added.

He also feared that some low end customers will struggle to adopt this additional cost as it is not for Bangladesh, it will happen due to the global phenomena.

Energy price hike is not an issue of Bangladesh only, almost every country facing the same challenges, especially the EU , is facing high challenges to maintain energy costs, he added.