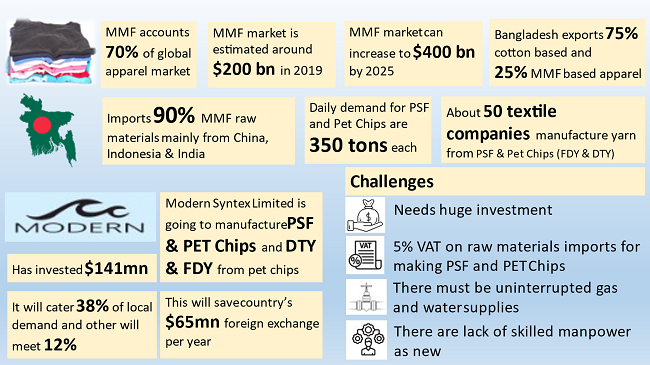

Currently, manmade fibers (MMF) account for over 70 percent of the global apparel market. However, 25% of Bangladesh’s exported garments are manmade fiber based and the remaining 75% are cotton based. Till now 90% raw material of this 25% manmade fiber had to be imported mainly from China, Indonesia and India. Now, Chittagong-based Modern Syntex Limited, a subsidiary of TK Group, is going to produce two major raw materials for the first time.

As the investors come forward to produce the main raw material of some products including manmade fiber clothes, shoes and other products in the country, it will be possible to reduce the import dependency by 50 percent by next January, the sector concerned believe.

According to a recent study by Grandview Research, a research firm based in the US and India, synthetic fibers are gradually taking over the international market for ready-made garments, which is estimated to be around $200 billion in 2019. And by 2025, the market for such clothing can increase to $400 billion.

Local sourcing of MMF raw materials will further boost our industry and increase the confidence of the buyers which will lead to more orders for Bangladesh in the future.

The two main raw materials that Modern Syntex Limited is going to manufacture are – Polyester Staple Fiber (PSF) and Polyethylene Terephthalate (PET) Chips. Apart from this, it will produce Drawn Textured Yarn (DTY) and Polyester Fully Drawn Yarn (FDY) from its own pet chips. They will start production on a small scale from next November and full-scale from January.

“This will save Bangladesh about $65 million foreign exchange per year and improve lead times, which will help Bangladesh to be competitive,” said Modern Syntex’s General Manager Shafal Barua.

The other two companies of the TK Group, Modern Poly Industries Ltd. and Super Synthetic, also produce two of the four main raw materials of manmade fiber, which are now market leaders in supplying those two raw materials. Apart from this, Bengal Synthetic and a company of Noman group produce small amounts of DTY and FDY.

Once MMF fabric was completely imported as the raw material of Bangladesh’s man-made apparel. At present, about 50 textile companies in the country have been able to import PSF, FDY and DTY and manufacture yarn from here to supply local fabric manufacturers.

The daily demand of PSF and pet chips in the country is approximately 350 tons. So far, DTY and FDY were produced from imported pet chips, but due to huge investment, no one went to produce PSF and pet chips. Modern Syntex Limited will be able to supply 60% of the demand for PSF and 30% of the demand for pet chips, said top officials of the company.

For this, Modern Syntex Limited has invested $141 million. Currently they have started some experimental production works. But the top officials of the company said that there are several challenges of investment in this sector.

First of all, it needs huge investment. Secondly, the main raw materials for making PSF and pet chips, refined terephthalic acid (PTA) and mono ethylene glycol (MEG), have to be imported and there is a 5% value added tax on the import of raw materials, which they feel is a hindrance in moving ahead in competition.

Thirdly, uninterrupted gas and water supplies are must, but there is challenge to get continuous gas and water supplies. And fourthly, there are lack of skilled manpower as this is the first such manufacturing in Bangladesh.