The market of recycled yarn is swelling worldwide, especially after the new environmental laws being formulated by the European Union (EU) but unfortunately, Bangladesh is still far behind the competitors in the production of such yarn due to many aspects including lack of policy support from the government. Because it is estimated that the fashion industry is one of the world’s greatest polluters responsible for about 20% of the planet’s wastewater and around 10% of the world’s greenhouse gas emissions. So the importance of yarn recycling getting a core focus in regards to sustainability among the end users and to all the stakeholders.

What is recycled yarn

The old and discarded clothing or scrap of garment that is produced by manufacturing processes, widely known as “jhoot” in Bangla are the main materials of yarn and fabric to recycle.

The Global Recycled Standard (GRS) set the criteria that a yarn can only be branded `recycled´ when spun with more than 20% recycled fibers. This specification is for tracking and verifying the recycled content of materials in a final product.

The market size of recycled yarn

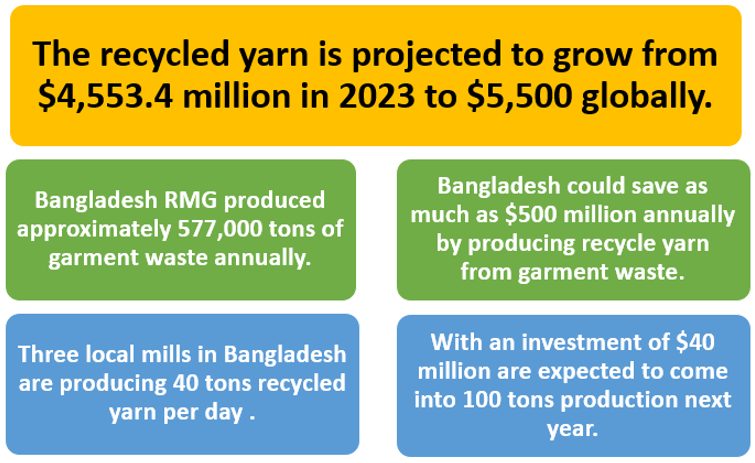

The recycled yarn is projected to grow from $4,553.4 million in 2023 to $5,500 as global annual sales. According to QY, a California-based global research organization, the growth of recycled yarn can be 7 million by 2029 at a compound annual growth rate of 3.2 percent.

Another source such as Straits Research says Recycled Textile Market Size is projected to reach USD 7.56 billion by 2030, growing at a CAGR of 3.6%.

Brands are focusing on recycled yarn.

Many giant retailers like Swedish Retail H&M set strategy as a part of the new rules and have a target to have 24 percent of its apparel sourced from recycled or sustainable materials by 2025.

Japanese Fast Retailing Company plans to use 50% recycled materials by 2030.

Delara Burkhardt, one of the MEPs behind the EU’s plans said “Consumers alone cannot reform the global textile sector through their purchasing habits. If we allow the market to self-regulate, we leave the door open for a fast fashion model that exploits people and the planet’s resources”. She also added that The EU must legally oblige manufacturers and large fashion companies to operate more sustainably.

The Bangladesh situation to produce recycled yarn.

In line with the world’s trend, there are only three local mills in Bangladesh for manufacturing recycled yarn. The mills are set up with an investment of around $30 million and they can produce nearly 40 tons of recycled yarn per day.

It is also found from different sources that approximately another 60 tons of recycled yarn are produced by some local mills that are used for domestic markets, such as mattresses and curtains.

Sources said there are four more projects under construction in Bangladesh with an investment of $40 million and are expected to come into production within the next year. The mills are expected to take the daily output of exportable recycled yarn to 100 tons.

Ayesha Shefa, Director of Sustainability & Head of Marketing, Simco Spinning and Textiles ltd (CYCLO recycled fibers) said to textile focus –

We are now fully operating in the recycled yarns business which means we are ensuring upcycling of the fabric mill’s cut clips waste. This waste is mostly exported to different countries. SIMCO has ensured intervention and upscaled this to a level that ensures that a circular economy is achieved as the clips waste and are resourcefully valorized within Bangladesh. Our business fluency also means we were able to grow and increase the employment of locals.

Ayesha Shefa also said SIMCO’s production capacity is focused on recycled yarns only. It is now predominantly producing CYCLO Recycled Fibers. This ensures one arm of the sustainability wing – environmental improvement. Through the production of these recycled fibers and yarns, there are intangible savings on air, water, land, and CO2.

Opportunity for Bangladesh to produce recycled yarn.

Research led by Global Fashion Agenda, with partners Reverse Resources, the Bangladesh Garment Manufacturers and Exporters Association (BGMEA) and which is supported by P4G, found that in 2019, Bangladesh produced approximately 577,000 tons of waste just from ready-made garments (RMG) and fabrics mills of which almost half (250 thousand tons) was 100% pure cotton waste. It is estimated that factories in Bangladesh could sell this 100% cotton waste to the recycling market for up to 100 million USD.

Bangladesh is currently heavily reliant on the import of textile fiber. In 2019, the country imported 1.63 million tons of staple cotton fiber (with a value estimated to be 3.5 billion USD). Based on the Circular Fashion Partnership findings, if just the 100% cotton waste was recycled within Bangladesh, imports could decrease by around 15%, therefore saving half a billion USD that would have been spent on cotton imports.

Bangladesh could save as much as $500 million annually if the cotton waste is generated. This is a big opportunity for Bangladesh to recycle the pre-consumer cotton waste produced by various RMG industries. So, the opportunity has been taken by many of the millers in Bangladesh.

Challenges for Bangladesh to Produce Recycle Yarn

Textile experts said that recycled yarn is an unavoidable fact, and that blending virgin and recycled cotton will make some quality parameters worse. So, the required technical experts are still not enough in the sector to produce quality recycled yarn.

To cope with the risks, better communication and a common understanding are needed throughout the textile value chain.

Mohammad Ali Khokon, president of Bangladesh Textile Mills Association said to a daily newspaper that a 7.5 percent VAT on procurement and 15 percent VAT on sale of such yarn has been hindering investment in this sector. The government should formulate policy in this regard soon, he added.

In conclusion, it can be said Bangladesh has a huge opportunity to grab the global recycled yarn market by utilizing the 577,000 tons of waste annually that comes out from various ready-made garment factories. The broader sense of sustainability lies in the recycling and reuse of production waste. As Bangladesh is the second largest RMG exporter so recycled yarn market also can be dominated by the country.