Jute has been used for centuries to make various products and is known for its affordability, biodegradability, and eco-friendliness. Jute is commonly referred to as the ‘golden fiber’ of Bangladesh.

According to the IMARC Group, the market size of jute bags is anticipated to reach $3.84 billion in 2027, with a CAGR of 10.4%. In Bangladesh, the jute industry contributes 1% to the country’s GDP and accounts for 3% of the overall export earnings.

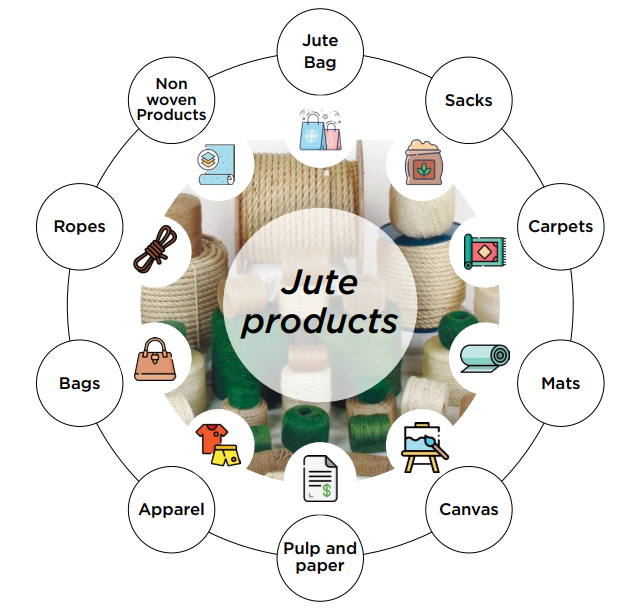

Figure: Diversified jute products are an impressive element for the export figures of Bangladesh capturing radical mark towards innovation.

Bangladesh exports jute products to more than 100 countries around the world. Some of the major importing countries include Australia, Belgium, Brazil, China, Djibouti, Germany, India, Indonesia, Ivory Coast, the Republic of Korea, Pakistan, Russia, the United Arab Emirates, the United Kingdom, the United States and Vietnam.

Jute based products

Bangladesh boasts a diverse range of jute products, numbering 285, which are exported to the world market. These products include raw jute, jute hessian, bags, sacks, ropes, carpets, caps, mats, carpet backing cloth, chair covers, jute sheets, canvas, pulp and paper, household products and non-woven textiles etc. Jute stick charcoal products are a byproduct of jute sticks. At present, Bangladesh produces around 3 million jute sticks annually.

According to the Bangladesh Enterprise Institute, the country has the potential to export jute stick based charcoal worth USD 3.0 to 3.5 billion. Jute-tin is another result of R&D by Bangladeshi scientists and is deemed as more durable (withstanding rust and saline) and stronger than metallic-tin.

Sustainable alternatives

It is becoming increasingly apparent that we should prioritize our relationship with jute over plastic. Plastic materials are responsible for the massive pollution across the globe. Moreover, plastic bags are not biodegradable; in fact, scientific analysis indicates that it may take as long as 2,000 years for plastic to decompose.

Even jute production requires less water per hectare of land than some cellulosic fibers like cotton. Jute cultivation is less likely to be pest free and thus mitigate any kind of soil problem in the field. Jute is carbon neutral crop. Studies showed that one hectare of jute plants can consume about 15 tons of CO2 from atmosphere and release about 11 tons of oxygen in the 100 days of the jute-growing season. Jute carbon footprint is way less than cotton, hemp.

Jute production uses less chemical in the processing including treatment and finishing segment of manufacturing. Pesticide usage is comparatively less than cellulosic fibers like cotton. The amount is substantially less than synthetic materials in general. As jute is 100% biodegradable and recyclable, it reduces deforestation in some instances.

Jute processing requires relatively less energy compared to the production of synthetic fibers. The manufacturing processes involved in transforming jute fibers into usable products consume fewer resources, making it an energy-efficient option.

Recent status of jute business

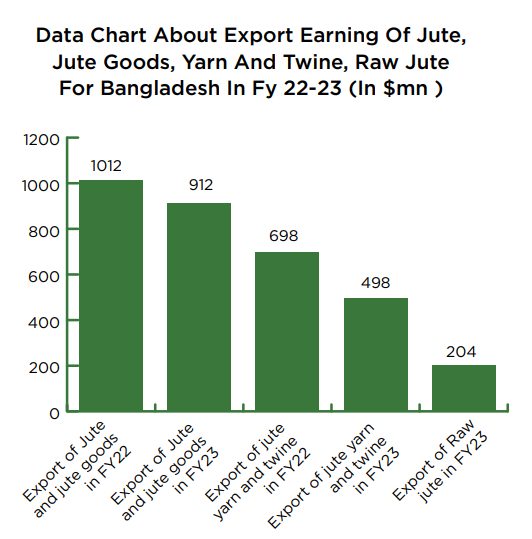

Latest data from the Export Promotion Bureau (EPB) shows export earnings of jute and jute goods fell by 19 per cent to $912 million in FY23, compared to $1.12 billion recorded in FY22.

Under the category, export earnings of jute yarn and twine have declined the most by 28.64 per cent to about $498 million in FY23. But in FY22, the amount was around $698 million. Export income from Jute sacks and bags rose by almost 8 per cent to $109 million in FY23, compared to the previous year. However, raw Jute export income decreased by 5.5 per cent to $204 million in FY23.

Despite having the possibilities of jute and its diversified products, we are seeing a steep decline in the export figure in the latest data. There are some distinguished reasons behind this issue.

The recently imposed anti-dumping duty by the Indian government –ranging from $19 to $352 per ton through a tariff notification — may have some adverse effects on exports. Due to the imposition of anti-dumping duties by India, many Bangladeshi jute mills have had to shut down operations.

According to recent statistics from the BJMA, out of its 202 members, only 132 jute mills are currently in production, and thousands of jute mill workers have lost their jobs as a result of the closures. High inflation cost is increasing the barriers between good quality product and the expense of the masses.

The government enacted the Packaging Act in 2010 to promote the use of eco-friendly jute products instead of polythene or polypropylene bags. This initiative is a great system of using jute in the local market. But reports analyze that, the implementation is very limited, resulting in a micro impact on jute usage.

Ongoing Russia- Ukrain war has a concerning impact on the jute export figure, as they are a big economical market for Bangladesh. The war in Sudan, one of the largest markets for Bangladesh’s jute products, has also affected shipments. Thus, the market price of jute has gone volatile and high in price. Even the low production capacity is a matter of impact on not meeting buyer’s requirement in given time. Jute millers also cited the country’s high production cost stemming from high energy prices, driven by the spike in both gas and electricity tariffs.

Steps to promote jute products

The Export Promotion Bureau (EPB) is organizing international fairs to showcase jute products. Jute fairs are also being held locally under the initiative of the Ministry of Textiles and Jute. Eventually, the tax rates must be lowered for the entrepreneurs who take loans from commercial banks for the expansion of jute business.

For reaching $100B export figure withing 2030 as per the report of BGMEA, Government must promote our cultural heritage, jute through action plans, studies, surveys, programs, projects, seminars, workshops and fairs to raise public awareness for the cultivation of more jute.

The shutdown of several jute mills has also been highlighted as a factor for the industry’s lag. The government cannot tolerate such losses permanently. Whatever the cause, it is in the national interest to increase jute product manufacturing and marketing. It is worth noting that the government has declared the National Jute Policy-2018, which prioritises the production of quality jute, ensuring fair prices for jute, diversifying jute goods and expanding the market for jute products.

Jute diversification must be practiced throughout Bangladesh through every industry. The pricing issues must be mitigated as soon as possible. The packaging sector around our country must implement jute as an alternative approach of polythene. Jute products must improve existing quality throughout its diversified products.