Experts have called for decoupling the economic growth from the environmental pollution by ensuring circularity in the industrial sector.

Circularity – meaning that a product, service, or resource is renewed or regenerated, rather than wasted – should be the key factor in the next growth transition of Bangladesh’s economy, said experts at the 1st edition of the “Bangladesh Circular Economy Summit” on Thursday.

Dutch Ambassador to Bangladesh Anne Van Leeuwen said, “Bangladesh has made tremendous progress in economic and social development indices. The country has the opportunity to be a leader in the circular economy too.”

Bernd Spanier, deputy head of the European Union delegation to Bangladesh, said circularity has become the main focus nowadays.

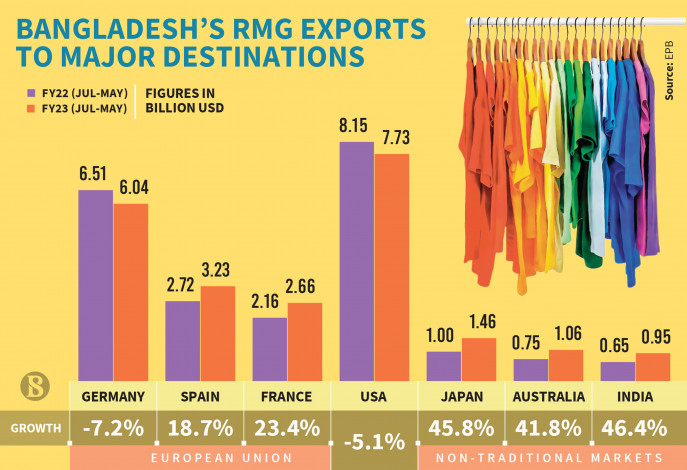

“Bangladesh is the second largest producer of the RMG products, meaning it is also the second largest producer of the apparel waste,” he said.

“With regard to circularity, the EU wants to help Bangladesh by knowledge sharing, and technology transformation. Events like the Circular Economy Summit should be arranged more,” he said, adding that Bangladesh should be the largest example of a circular economy.

Leyla Ertur, head of sustainability at H&M Group, said, “The fashion industry needs to accelerate its transformation towards circularity as the way forward to solving the biggest challenges we face, such as climate change and biodiversity loss.

“We need to join forces to build a circular fashion ecosystem, and Bangladesh is unique as the country with the world’s largest share of pre-consumer textile waste readily available for recycling.”

Bangladesh has a great potential to attract investments from local and foreign investors to scale up the production of high-value recycled fibres from pre-consumer waste, she continued.

“We have to work together to achieve circularity goals. In this regard, investing in research and development should be increased,” she said, adding, “H&M is now working on second-hand clothing, repairing, and recycling.”

Edimon Ginting, country director, Bangladesh Resident Mission, the Asian Development Bank (ADB), said the RMG sector is one of the top polluters. It contributes both to growth and pollution, so these aspects should be balanced. In this regard, the ADB will assist Bangladesh, which has to focus on waste management.

Dhaka North City Corporation Mayor Md Atiqul Islam said that 3R – reduce, recycle and reuse – are the keys to ensuring sustainability.

“Moreover, extended product or producer responsibility as stipulated by the EU is going to be mandatory for apparel producers in Bangladesh. So, the importance of promoting circular fashion in the country cannot be overstated,” he added.

Member of Parliament Saber Hossain Chowdhury, special envoy to the prime minister and chairman of the Parliamentary Standing Committee on environment, forests and climate change, said in a traditional linear economy, people produce, consume, and throw away – which is not sustainable.

“So, we need to make the shift from linear to circular economy to keep resources in use for as long as possible, and extract and harvest the maximum value from the products whilst in use. For that the business case for circularity has to be win-win for manufacturers and buyers,” said Saber Hossain Chowdhury.

“We have to think beyond corporate social responsibility as it is not the only way to sustainability. The business case for sustainability must be very strong. We have to make strong commercial sense,” he added.

Founder and CEO of Bangladesh Apparel Exchange Mostafiz Uddin said the Bangladesh Circular Economy Summit aims to find out the opportunities for the shift from the linear to circular business model and foster collaborations among the stakeholders to promote a circular economy in the country.

The Bangladesh Apparel Exchange in collaboration with Laudes Foundation, P4G, GIZ, Embassy of the Kingdom of the Netherlands in Bangladesh and H&M Group organised the programme.

Infographic: TBS

Infographic: TBS