Bangladesh RMG exports to Brazil grow 73%

Defying odds and economic crisis, apparels exports to Brazil performed well and posted a sharp growth by 73% during first ten months of the current fiscal year.

However, the export amount is still insignificant compared to its potential and size of the economy. As a non- traditional expert market Brazil holds enormous potential and offers a good opportunity to grow there for the country’s clothing products makers.

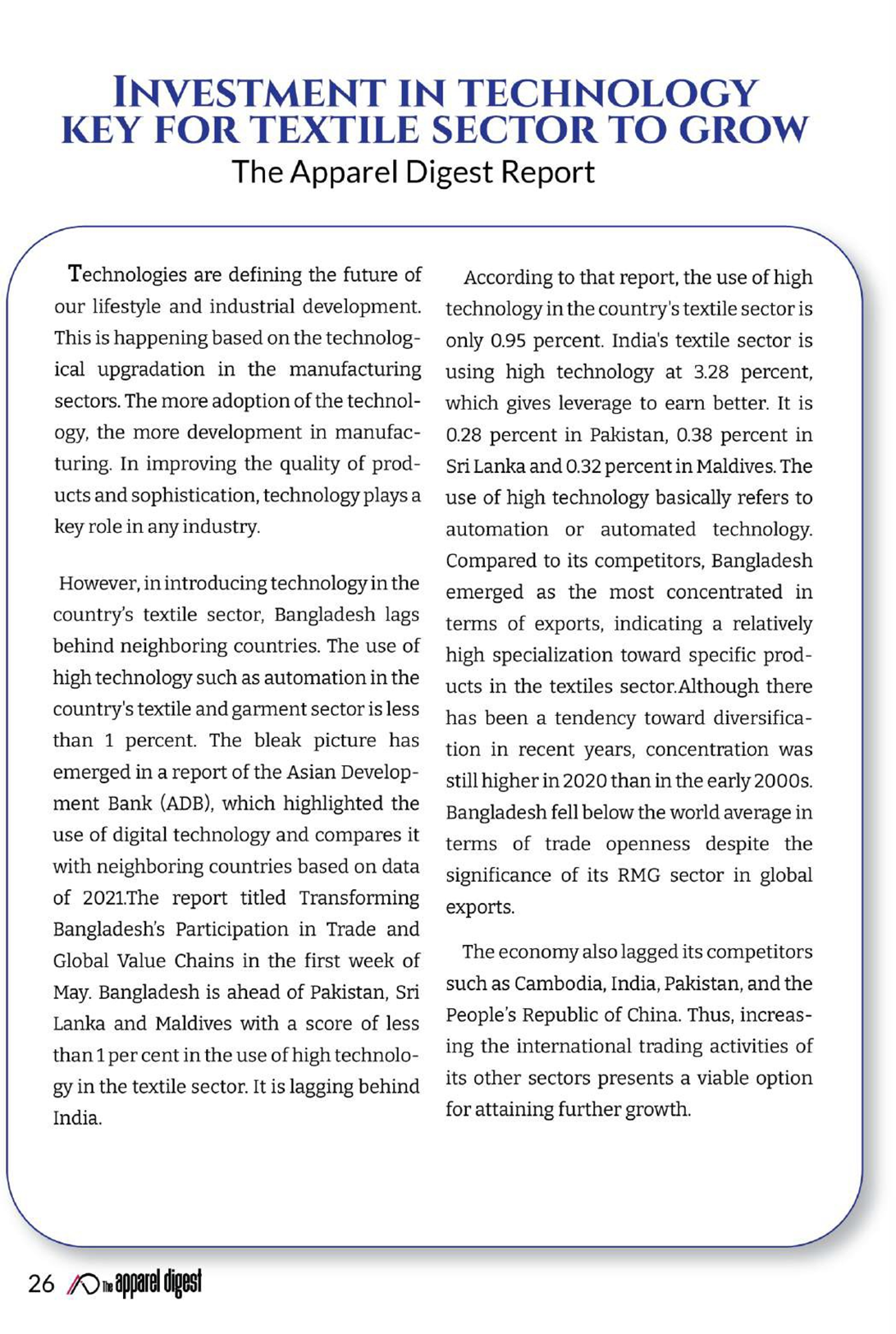

Figure: Bangladesh apparel items shipment to Brazil, increased by 73 percent to $139 million during the first ten months of the current fiscal year. During July-April period of FY22, Bangladesh earned $81 million.

According to Export Promotion Bureau (EPB) data, Bangladesh apparel items shipment to Brazil, increased by 73 percent to $139 million during the first ten months of the current fiscal year. During July-April period of FY22, Bangladesh earned $81 million.

Out of $139 million, $86 million came from knitwear items, which is 75.51% higher compared to $49 million the same period of last year. Woven products recorded a 65% growth to $53 million, which was $32 million a year ago.

As per the EPB data, overall apparel export to non-traditional exports market grew by 30.80 percent to $7 billion during July-April period of the current fiscal year. In the same period of previous fiscal year Bangladesh earned $5.35 billion exporting apparel goods to non-traditional markets.

Exporters’ initiatives to explore new markets and buyers and government cash incentives against exports to non-traditional markets attributed for the robust growth.

“We have focused on exploring new markets and new buyers. On the other hand, exporters participated in different types of expos, which also helped a lot to grow in the new market as well as Brazil,” said Bangladesh Garment Manufacturers and Exporters Association (BGMEA) President Faruque Hassan.

But the present export volume is very small compared to the market size of Brazil and its potential. We have to plan to hold a single country exposition to tap the opportunity to its fullest, he added.

Cash incentives against exports to non-traditional markets also is another reason for rise.

“Government is providing cash incentives against the exports to new markets to increase exports, Brazil is a new market and we are working with the Brazilian counterpart to improve bilateral trade,” said Senior Secretary of the Commerce Ministry Tapan Kanti Ghosh.

“Amid the high dependency on traditional markets, rise in non-traditional export markets is a good sign for Bangladesh. But the potentials are untapped,” said AB Mirza Azizul Islam, an economist.

To capture the opportunities, we have to properly use the commercial wining and other diplomatic channels. Similarly, exporters need to engage more bilateral business to business meetings to explore avenues, he added.

Currently, the joint chamber is working closely to improve bilateral trade relationship and in the coming days the trade between two countries will cross $2 billion.

Bilateral trade is in Brazil’s favor as we import more than exports. Trade volume is nearly $2 billion s per latest data.

Bangladesh imports sugar, wheat, and cotton from Brazil and exports apparel products, pharmaceuticals, plastics, tableware, vegetable textile fibre, jute goods, and manmade filaments.

In February, the Federation of Bangladesh Chambers of Commerce and Industry (FBCCI) and the Brazilian Trade and Investment Promotion Agency (ApexBrasil) signed a memorandum of understanding (MoU) to work together for the further expansion of bilateral trade relations.

Business Director of ApexBrasil Ana Paula Repezza and FBCCI president Md Jashim Uddin signed the agreement at ApexBrasil’s headquarters in Brazil.