All over printing started its journey in our garment industry from the 80’s. Although initially roller printing technique was prevalent, later flatbed and rotary screen printing techniques gained popularity. Peoples tastes, preferences and needs are changing with the change of era. Especially today’s young society is much more aware of their dress and fashion. Therefore, the demand for all over printing is increasing day by day all over the world including Bangladesh. There are many more products including t-shirts, shirts, pants, three-piece, bed-sheets and so on where all over print is being used. However, there are several limitations to the methods of all over screen printing, one of which is – all kinds of design can not be printed by using flatbed or rotary screen printing method. All though it is possible to print 1-20 colors by those methods, usually more than 12 colors are not printed, the main reasons are two: 1) Print cost is high & 2) Machine complexity. Also, the photo print and effect of 3D cannot be clearly highlighted through screen printing methods. A new chapter has been added to the printing industry to overcome all these various problems, that is Digital Textile Printing.

What is Digital Textile Printing?

Digital textile printing is a method where colorful designs are embossed on a variety of fabrics using digital ink-jet printing technology, i.e., any design can be easily and accurately printed on fabrics. Digital textile printing is one of the most promising developments in the textile industry. Maintaining the design quality, digital textile printing has opened the door to many possibilities to meet the growing demand for textile printing. This printing technique does not require any screens and there are no color limitations. Digital printing is also the ideal technology for printing 3D designs. Using this technique can be printed on fabrics, and also printed directly on garments like t-shirt, shirt, jeans etc.

Digital Textile Printing in Bangladesh

Digital printing was first patented in 1968 and gained popularity in 1990. In 2015, Beximco Group used digital textile printing machine for the first time in Bangladesh. At present, there are almost 20-22 factories in Bangladesh like Square Group, Liz Group, Knit Concern, Padma Textiles, Fortis Group, Mondol Group etc. that have digital textile printing machine. About 60% of total digital prints are made in Bangladesh, India, Indonesia, Pakistan & Vietnam. Today, Bangladesh has gained the skill and ability to compete with any country in the world with All Over Printing (Screen printing) and has created a strong position, but we are still so much behind in All Over Digital Printing.

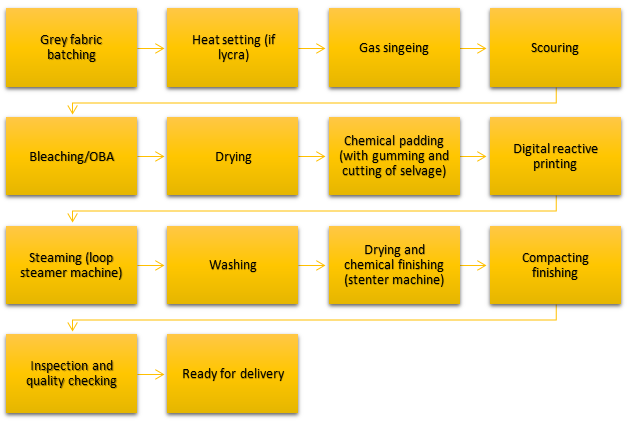

Continuous Process Flowchart for Digital Textile Printing:

How is Digital Textile Printing Done?

Let’s take a look at how digital textile printing works. A typical process flow has been explained below-

- Design Development

- Fabric Preparation

- Ink Selection

- Printing

- Fixing

- Washing

Design Development: The first task for digital printing is to create a design according to buyer’s requirements. A design developer/artist creates colorful design with the help of graphic software like Adobe Photoshop (sometime Adobe Illustrator) and CYMK color model is used as the basic color. Designers generally used the TIFF files for printing, to maintain the quality of artwork. If the design is original, the hand-done artwork is scanned and converted to digital format, and of course the design does not have firm borders to repeated many times. Now this digital image can be transferred to the fabric.

Fabric Preparation: Before the printing process, we have to pre-treat the fabric with liquid (chemical) solutions. Generally, cotton, viscose fabrics are ink-jet printed with reactive dye. So that, during this method thickener, alkali and urea are used that prepare it to accept the dye/ink and better absorb the color. Fabric preparation process helps to remove the fabric crushes and makes it stiffer for better feeding during printing.

Ink Selection: Now the question is what kind of ink can be used? What kinds of ink is needed depends on what kinds of fabric we are using. Some common types of ink are discussed below-

- Pigment Ink: It is generally used for both natural and synthetic fabric printing like cotton, silk, rayon, cotton/poly blends, and 100% polyester. There are 8 colors (Cyan, Magenta, Yellow, Black, Gray, Orange, Violet and Red) in the ink set.

- Acid & Reactive Ink: These two are dye-based inks, which is used for natural fibers. Hand feel & wash fastness of dye inks are very good. Dye ink penetrates the fabric very well but in order to make it usable, several processes have to be completed such as pre-treating, heat, washing and steaming. Reactive ink is used for digital printing in Bangladeshi factories.

- Sublimation/Disperse Ink: Sublimation ink is used to make banners, soft signage, sportswear, where the fabric is typically high content polyester and spandex. There are 15 colors are available in this set. Sublimation/disperse inks are transferred to the fabric directly or with the help of receptive paper roll.

| Ink Characteristics of Digital Textile Printing | |||

| Ink | Fabric Type | Pre-treatment | Post-treatment |

| Pigment | Natural, Synthetic | No (Usually) | Dry heat |

| Acid | Wool, silk, Nylon | Yes | Steam heat |

| Reactive | Cotton, Rayon, Silk | Yes | Steam heat |

| Disperse Dye | Polyester | yes | Steam or dry heat |

| Disperse sublimation | Polyester | No | Dry heat transfer |

Printers & Printing: Generally, digital textile printing uses ink-jet technology and ink cartridges. The pretreated fabric is then sent to a digital printer, where the machine sprays ink/dye with tiny droplets as ordered by the design and software. At first, the fabric is set smoothly and with proper tension to avoid the miss prints. Then the heads of printing machine are set according to the fabric thickness and fabric width. So that, the more machine heads, the more the production. There are many kinds of digital printing machine such as-

- Direct-to-Textile Printing: In this case, the printer transfers ink directly-to-the fabric or directly-to-garments with the help of ink-jet technology. With this method it is possible to print most detailed artwork/design. Using this method, it is possible to printing different types of fabric like cotton, silk and nylon.

- Sublimation Printing: This is one of the modern printing techniques. In this process, dyes are converted to gas by applying heat & pressure and attached to the surface of the polymer-based fiber (Polyester). It works fantastic for short runs and allows for highly detailed design.

- Disperse Dye Sublimation: This method eliminates the need for transfer paper for printing process. The fabric is passed through a heat press for dye fixation. In this case, the fabric is pretreated before printing. This printing technique allows for two-sided printing.

Fixing: The final step is fixing. Fixing means the permanency of the design. It depends on the type of fabric and dyes. Fixation is done through a number of processes depending on the fabric and printing method.

- Pigment Ink – Dry Heat (Usually through a roll fixation Calendar or Heat Press)

- Acid Dye – Steam – Wash – Dry (Usually large Industrial specialized equipment)

- Reactive Dye – Steam – Wash – Dry (Usually large Industrial specialized equipment)

- Dispersed Dye/ Sublimation – Dry Heat (Usually through a roll fixation Calendar or Heat Press)

Washing: After dye/ink fixation the fabric is washed and dried properly.

Some Common Brands of Digital Textile Printing Machine

| Durst Alpha | Italy |

| Zimmer Machine | Germany |

| Atexco Machine | China |

| Reggiani | Italy |

| MS | Italy |

| Homer Digital Printer | China |

| Mimaki | Japan |

| Epson | Japan |

Advantages of Digital Textile Printing

- There is no color limitation. As a result, highly detailed artwork and better sharpness can be attained.

- No need of screen during digital printing.

- Uses of water is 90% less and electricity is 30% less than traditional printing process. Because, there is no need to wash screens in applying new colors.

- Required less manpower than traditional printing.

- In digital printing, there is no need to do any calculation of repeat measurement. Design of any measurement can be developed.

- Design can be developed with high resolution (300-1200 pixel/inch). So that, printing quality is higher.

- No need of screen engraving and color separation, i.e., this process is cost effective.

- Less wastage of dyes/inks and chemicals than flatbed or rotary screen printing.

- Lower fixed cost and lower sample cost are the top benefits of digital textile printing.

- Low capital investment.

Limitations of Digital Textile Printing

- In digital textile printing, all types of fabric can be print except blended fabric.

- In case of digital printing, printing is not done on deep color fabrics.

- If the resolution is higher, it takes more time to develop the design.

- Digital printing cost is very high, but it’s reducing day by day.

- Lower production. It depends on the machine head. The higher the machine head, the higher the production. Generally, the production rate is 1-3 meter/min.

- It is not possible to digital print in any temperature. The temperature might be 250 We have to do digital print in AC room, otherwise if the temperature rises, the machine will stop automatically and the ink will coagulate and print head will be damaged.

- The heads of digital printers cannot be reused.

Faults of Digital Textile Printing with Remedies

Color Staining

Causes: In case of dark color printing, color staining is appeared in the unprinted area.

Remedies: Fabric should not come into the contact with each other during loop formation in steaming. Coating recipe should be suitable. Clearly remove the excess color.

White Spot

Causes: Due to uneven singeing.

Remedies: Remove protruding fibers from the fabric surface properly before coating. Chemical tank should be clean.

Low Color Yield

Causes: Uneven singeing and mercerizing. Unsuitable coating chemical.

Remedies: Singeing and mercerizing process should be done properly before coating and also using suitable coating chemical.

Shade Variation

Causes: Most critical problem we face in digital textile printing is shade variation. Printing the design perfectly with correct shade but, after finishing we get different shade. Due to improper chemical coating and finishing parameters shade variation appears.

Remedies: Recipe of chemical coating should be perfect and maintain the viscosity & pH of coating solution. During steaming, washing and finishing, all the parameters should be proper.

Global Digital Textile Printing Market Size & Growth

There is no doubt that the global pandemic has brought economic crisis, but it has also provided many new commercial opportunities in the textile industry. According to the article of Federation of European Screen Printers Associations (FESPA), despite the global COVID-19 crisis and the economic downturn, the digital textile printing market worldwide will still grow to 7.7 billion square meters by 2027 at a CAGR of 3.6% from 2021 to 2027.

In May 2020, Allied Market Research predicted that the market value of global digital textile printing was US $2.2 billion in 2019, which will increase to US $8.8 billion by 2027, at a CAGR of 19.1% from 2020 to 2027. The growing demand for digital technology for textile printing and sustainable printing in the garments & advertising industry are expected to have a positive impact on production demand.

In July 2020, Research and Markets said that the global digital textile printing ink market size was US $1112.0 million in 2019. It was projected to reach US $2665.7 million by 2027, at a CAGR of 11.6% from 2020 to 2027. Similarly, according to Persistence Market Research on digital textile printing machinery- the global market for digital textile printing equipment is expected to reach US $2.25 billion by the end of 2028, at a CAGR of 14.9% (During the forecast period)

Opportunities of Digital Textile Printing in Bangladesh

Although Bangladesh did fantastic in All Over Printing (Flatbed & Rotary Screen Printing), but Bangladesh is still far behind in All Over Digital Printing. Lack of skilled manpower, application of poor technology, use of low-quality raw materials are the main reasons for this situation. Also, we have no opportunity to learn about digital printing technology. This is why graduates and experienced technicians cannot enrich their knowledge about digital textile printing. Our main competitors like China, Pakistan, Turkey are advancing very fast in printing industry. We need to take several steps to overcome these problems, such as: AOP and Digital Textile Printing topics to the academic curriculum, so that they can come up with basic ideas from the very beginning. Those who are fairly proficient in theses topics can enter the industry with practical knowledge if printing experts and industry leaders collaborate with the universities/colleges and arrange training for the students. As a result, our new generation will be able to know about new technologies and innovations.

Conclusion

Digital textile printing technology has opened the door to creativity by encouraging photographic reproduction, creating detailed designs and experimenting with brand new applications. The expansion of printed t-shirt sector involving the evolution of Direct-to-Garments (DTG) technology is a phenomenon that has grown rapidly. The current market demonstrates some new innovations in digital textile printing like continuous inkjet, electrophotography, thermal inkjet etc., each technology having different and unique characteristics, benefits and limitations. So, we should work harder with these latest technologies and innovations, so that we can reign supreme in the digital textile printing sector as well.

Major References

- https://study.com/academy/lesson/digital-textile-printing-machine-process.html

- https://www.southerntailors.com/blog/3-digital-fabric-printing-techniques-advantages-and-disadvantages/

- https://gotxfabricprinter.com/eu/wp-content/uploads/sites/7/2014/10/How-Digital-Print-Works_10.14.pdf

- https://www.onlineclothingstudy.com/2011/06/digital-textile-printing.html

- https://www.fespa.com/en/news-media/features/market-trends-the-vibrant-future-for-digital-textile-pinting