The world’s leading supplier of textile machinery Rieter showcased its latest air-jet spinning machine at the recently concluded ITMA 2023 in Milan. Marc Schnell, Head of Product Management Air-Jet Spinning at Rieter shared his thoughts with Textile Today. Here is a glimpse of the discussion.

Figure 1: Marc Schnell, Head of Product Management Air-Jet Spinning at Rieter

Textile Today: What were Rieter’s latest technology highlights?

Marc Schnell: We showcased here at ITMA 2023 our latest innovation, the air-jet spinning machine J 70. The revolutionary double-sided air-jet spinning machine J 70 with up to 200 autonomous spinning units and four robots allows production speeds of an unmatched 600 m/min. Newly developed technology components provide increased delivery speeds in all applications.

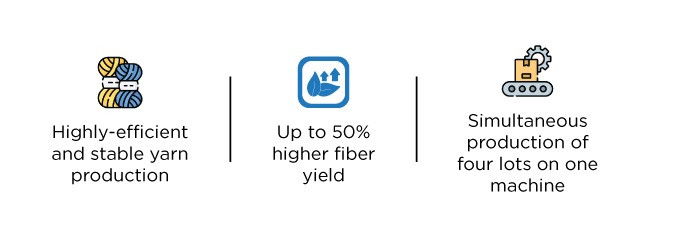

Figure 2: Features of the air-jet spinning machine J 70.

The J 70 easily masters a high level of yarn breaks at high speeds, while keeping productivity stable.

With the air-jet spinning machine J 70, production costs are significantly reduced thanks to lower energy consumption and up to 50% higher fiber yield compared to the competition.

With the J 70, spinning mills are ideally equipped to exploit the growth potential in standard and blended yarns. For example, fashionable high-quality soft yarns made from polyester-cotton or polyester-viscose blends can be produced economically and efficiently with the new air-jet spinning machine J70.